The technology behind Premera coatings and primers and their unique performance is called sol gel. Sol Gel based coatings are actually a relatively old advancement in material science, but before diving in to how Premera innovated and advanced sol gel technology, we will answer: what is a sol gel?

Let’s break it down.

Sol-Gel

First, what is a sol? A sol is essentially an extremely small solid particle, typically nanoparticle, of any element or molecule.

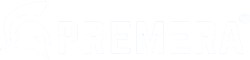

We like to start off explaining sol gels by first giving a related example most people are familiar with: aero-sols. People are familiar with aerosol cans, but another common aerosol is smoke. Smoke, while it behaves like a gas, is actually entirely comprised of solid particles. The extremely tiny particles are carbon – so, in smoke’s case, the “sol” is tiny solid particles of carbon. The “aero” in aerosols means air. Aerosols, like smoke, are classified this way because the sols – tiny solid particles – are in close proximity in the air and are behaving like a gas. If you made a campfire inside, eventually there would be a black, powdery layer of carbon on the ceiling from the rising smoke. While the smoke looks and behaves like a gas, when it touches the ceiling, all of the tiny particles of carbon land on the ceiling and stay there.

Sol-Gel

An aerosol is large amount of sols, tiny solid particles, in the air behaving as a gas. A sol-gel is a large amount of tiny solid particles, but they are behaving as a liquid. While the sol in smoke is carbon, the sol in Premera’s sol-gels is silicon dioxide, or quartz, meaning Premera sol-gel based coatings are essentially liquid quartz.

The Innovation

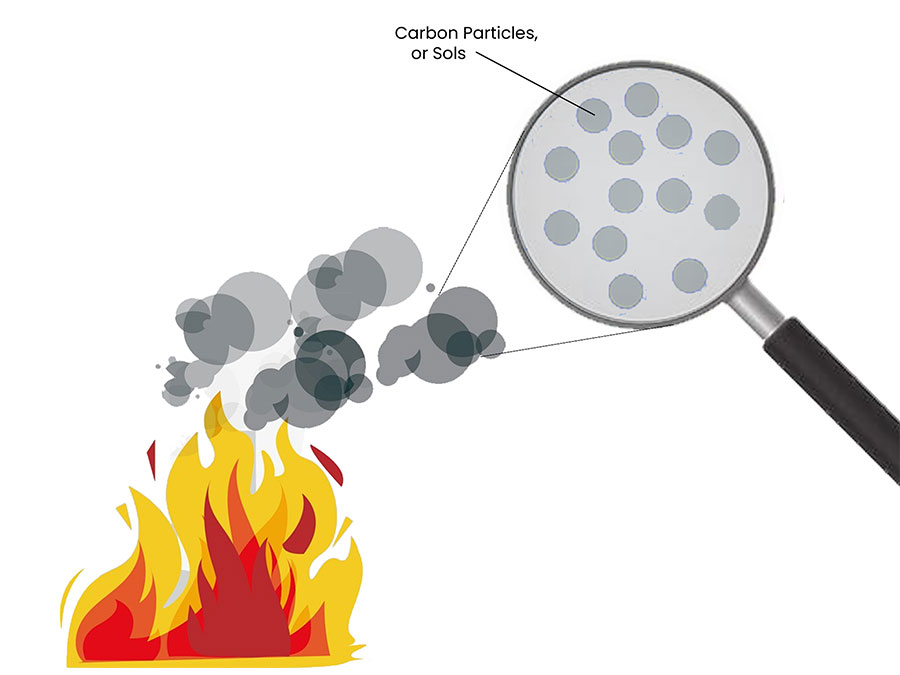

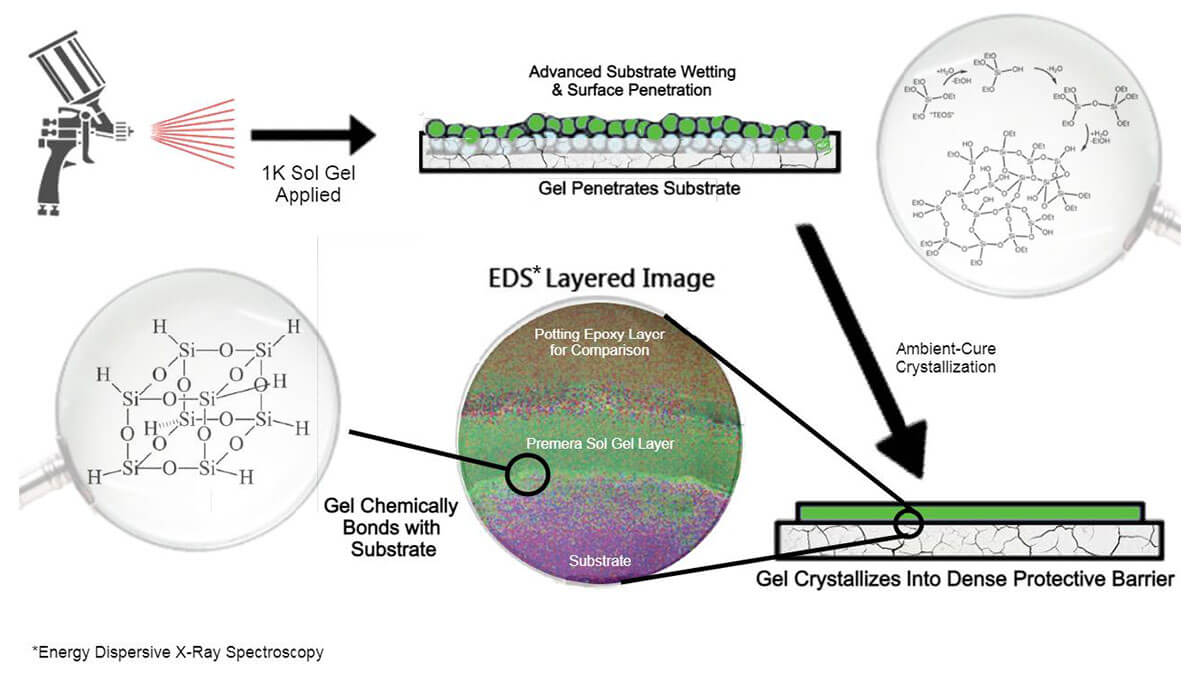

Now that we have sol-gel defined, we can explain Premera’s innovation. Sol-gels were actually first successfully commercialized in the 1960s. Their first big success was in the automotive sector. Metal bumpers, mirrors and other glass or metal vehicle parts were coated with sol-gels for better scratch resistance, and commonly they were silicon dioxide sol-gels, similar to Premera sol-gels. The challenge with earlier sol-gels was the environmental conditions that had to exist for the sol-gel to crystallize into a solid coating layer. The first sol-gels had to be heated up to 500-600F or higher for up to an hour in order to crosslink, or bond together, and crystallize into a solid coating – similar to heating a ceramic pot in the oven to get it to harden.

Premera’s innovation in sol-gels occurred in 2012. Instead of needing 500F+ temperatures to get our sol-gels to turn crystalize into a solid layer of quartz, our sol-gel based coatings cure out and crystalize in normal ambient conditions, anywhere from 45F – 105F. This innovation unlocked sol-gel technology so that it can be used in everyday environments from a new construction building to a kitchen countertop. Ambient curing of sol-gels is only half of what makes Premera coatings and primers unique.

Silanes

Enabling a solid quartz film to crystallize into a protective layer on a surface in ambient conditions is significant, but how the crystal layer is adhering to the surface is the other key to Premera sol-gel performance. Premera sol-gel based products utilize silanes to adhere to surfaces. Silanes are unique because they have excellent adhesion to both inorganic materials, like concrete, tile, glass and metal (materials that do not have carbon) and also organic materials like paints and plastics which include epoxies, acrylics, urethanes, polyaspartics, polyureas and other materials that are carbon based, which is what defines organic material. They have excellent adhesion to both because they can chemically react with and become part of both organic and inorganic materials. This means, silanes are forming chemical bonds as opposed to mechanical bonds.

Mechanical Bond vs Chemical Bond

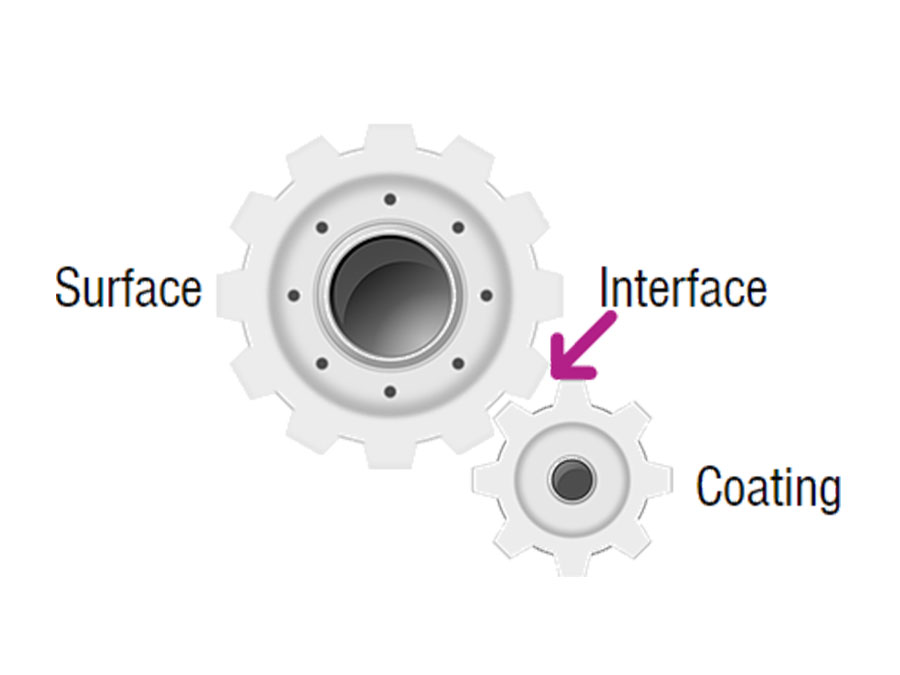

Normally, inorganic materials can bond strongly together if they are in a liquid state, which typically involves very high temperatures – think welding. Organic materials like epoxies and polyurethanes can bond strongly together if applied correctly and while crosslinking is still occurring, which is why you must top coat epoxy within a certain window of time. However, inorganic materials, like concrete, and organic materials, like epoxy, are not able to adhere to each other unless there is a very strong profile on the surface. This is why grinding or shotblasting is done to concrete to get epoxy to adhere to it. A profile is created in the surface from grinding, and then epoxy (or other organic coating) is applied, fills the profile, cures out and hardens becoming locked into the surface like two gears fitting together. This is called a mechanical bond. If the profile is not there, the epoxy and concrete will never adhere to each other.

What makes silanes different? Silanes are able to react with and become part of both inorganic materials like concrete, and organic materials like conventional epoxies, urethanes, acrylics, etc. Silanes react with OH groups, which both inorganic and organic materials have, and become part of the molecular makeup of the material. Silanes are chemically reacting with materials, and therefore do not need a profile to adhere. Silanes adhere just as strongly to polished concrete as ground concrete because they are reacting with concrete. Surface profile does not matter, only the surface material.

The Combination

Premera combines its advancement in sol-gel technology with the power of silanes. Premera products create a quartz crystal protective layer on surfaces that is highly abrasion resistant, chemical resistant, and UV resistant so the can be used indoors and outdoors. Because of the silanes used, there is no profile required to strongly adhere to both concrete, metal, glass, tile, but also epoxies, urethanes, polyureas, acrylics and other paints and coatings.

Premera clear coats are all single component, spray down coatings that self-level and do not require back rolling. They can be applied as top coats for polished or unpolished concrete, tile, glass, metal, and also epoxy, polyurethane, acrylic and other types of coatings.

Premera primers are able to bond epoxy and other types of coatings to concrete without needing to grind concrete. There are also able to bond coatings to tile without needing any type of profile on the tile, even glazed ceramic tile. If silanes can react with the material, then there is no longer a need to grind or profile the material to get coatings to bond to them. This is the power of Premera sol-gel technology.